Niaj hnub no, daim ntawv thov ntawm cov cuab yeej siv tshuab yog nrov heev, thiab ntau yam kev lag luam tau koom tes nrog cov ntsiab lus ntawm cov tshuab automation.

Rau kev txhaj tshuaj molding processors, "lub sij hawm yog nyiaj".

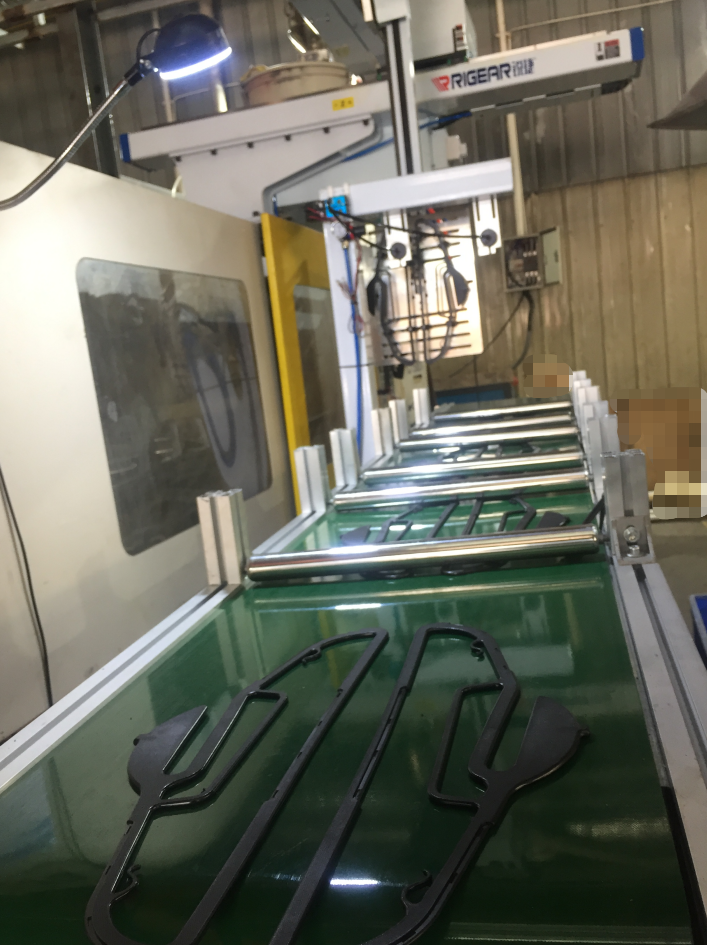

Yog xav txhim khoyas hangersntau lawm efficiency,

Tom qab ntawd yuav tsum sib tw sib tw rau lub sijhawm, siv kev nrawm dua, hloov tau yooj yim, thiab cov khoom siv neeg hlau ntau dua los ua kom cov khoom siv tau zoo, yog li txhim kho kev tsim khoom.

Kev siv cov khoom siv rau kev txhaj tshuaj molding tshuab tuaj yeem tiv nrog cov teeb meem ntawm kev ua haujlwm siab,shortened txhuas lub sij hawm, thiab kev ua haujlwm zoo.

Tsis tas li ntawd, tus neeg hlau tuaj yeem ua kom muaj kev sib luag ntawm lub voj voog ua haujlwm, txhim kho qhov zoo, thiab muaj kev nyab xeeb dua.

Rau kev ua lag luam thiab cov neeg siv khoom xav tau, pebHometime Hoobkastsis tsuas yog nthuav tawm cov qauv kev cob qhia tshiab,

tab sis kuj siv cov manipulators los koom tes nrog peb cov tshuab txhaj tshuaj rau pebkhaub ncaws hangersntau lawm.

Nws tau txhim kho peb lub Hoobkas kev ua haujlwm ntau lawm.

Cia peb tham txog qhov zoo ntawm cov manipulators.

1. Kev nyab xeeb siab:Kev siv lub tshuab ua kom tsis txhob muaj kev phom sij ntawm tes raug mob vim kev txhaj tshuaj molding tshuab tsis ua haujlwm lossis ua haujlwm tsis raug,

nrog rau cov xwm txheej hauv kev lag luam los ntawm kev tsis saib xyuas lossis qaug zog ntawm cov neeg ua haujlwm.Tshwj xeeb tshaj yog rau kev txhaj tshuaj molding tshuab loj.

2. Lub sijhawm voj voog ruaj khov:cov zis txiav txim siab txog kev txaus siab mus sij hawm ntev.

Tib cov nroj tsuag, cov khoom siv tib yam, thiab cov xwm txheej zoo ib yam, vim muaj kev ruaj ntseg ntawm lub voj voog ntau lawm, kev siv cov neeg hlau yuav zoo dua rau covcov hangerstso zis.

3. Kev ua haujlwm siab:Nws tuaj yeem txhim kho lub sijhawm tsim khoom ntawm txhua yam khoom pwm, thiab tib lub sijhawm plasticizing, lub sijhawm txhaj tshuaj, lub sijhawm tuav lub sijhawm, lub sijhawm txias,

thiab pwm qhib thiab kaw lub sijhawm tuaj yeem txhim kho cov txiaj ntsig ntawm cov khoom tau yooj yim.

4.Txuag raw khoom:Lub sijhawm rau cov neeg ua haujlwm tawm yog tsis paub tseeb,uas yuav ua rau cov khoom shrinkage thiab deformation

(yog hais tias cov khoom siv lub raj yog overheated, nws yuav nkim raw cov ntaub ntawv yog tias nws yuav tsum tau rov txhaj tshuaj).

Lub manipulator yuav siv sij hawm ntev, yog li qhov zoo yog ruaj khov.

5. Tiv thaiv pwm kev puas tsuaj:Yog tias tus neeg ua haujlwm tsis tuaj yeem tshem tawmyas khaub ncaws hangersua tiav, cov pwm clamping yuav ua rau puas pwm.

Yog hais tias tus manipulator tsis tshem tawm covtsho tiv no hangersntse, nws yuav cia li tswb thiab nres.

6. Kev txuag nyiaj ua haujlwm:Lub manipulator tshem tawm cov khoom thiab muab tso rau ntawm txoj siv conveyor lossis lub rooj txais.

Tsuas yog ib tus neeg yuav tsum tau saib xyuas nws lossis ib tus neeg tuaj yeem saib ob lossis ntau qhov kev txhaj tshuaj molding tshuab tib lub sijhawm, uas tuaj yeem txuag kev ua haujlwm.

7. Txhim kho cov khoom zoo:Lub manipulator tau txais cov khob uas tsis yog cov qauv nqus kom siv zog txawm tias lub sijhawm clamping yog tsau, thiab pwm kub yog qhov qub,

uas tuaj yeem txo qhov tsis xws luag ntawm cov khoom thiab txhim kho cov khoom zoo.

8. Txhim kho kev sib tw:siv manipulators los txhim kho cov duab ntawm lub rooj cob qhia,

xyuas kom zoo, ntau yog xam cov zis, thiab txhim khu kev sib tw ntawm lub lag luam.

Welcome to contact us for any business discussion.Email : carey@hometimefactory.com

Post lub sij hawm: Jun-17-2022